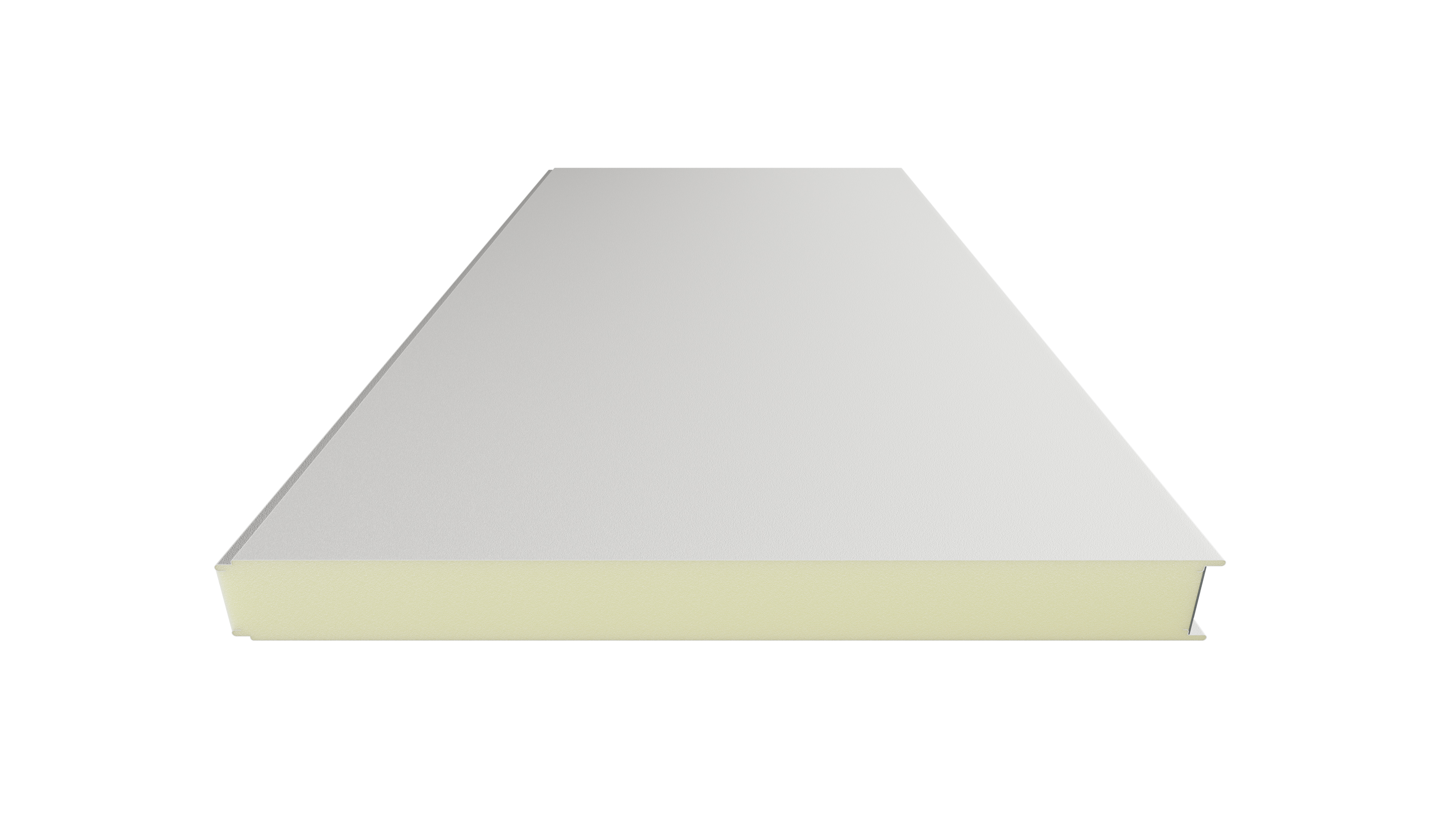

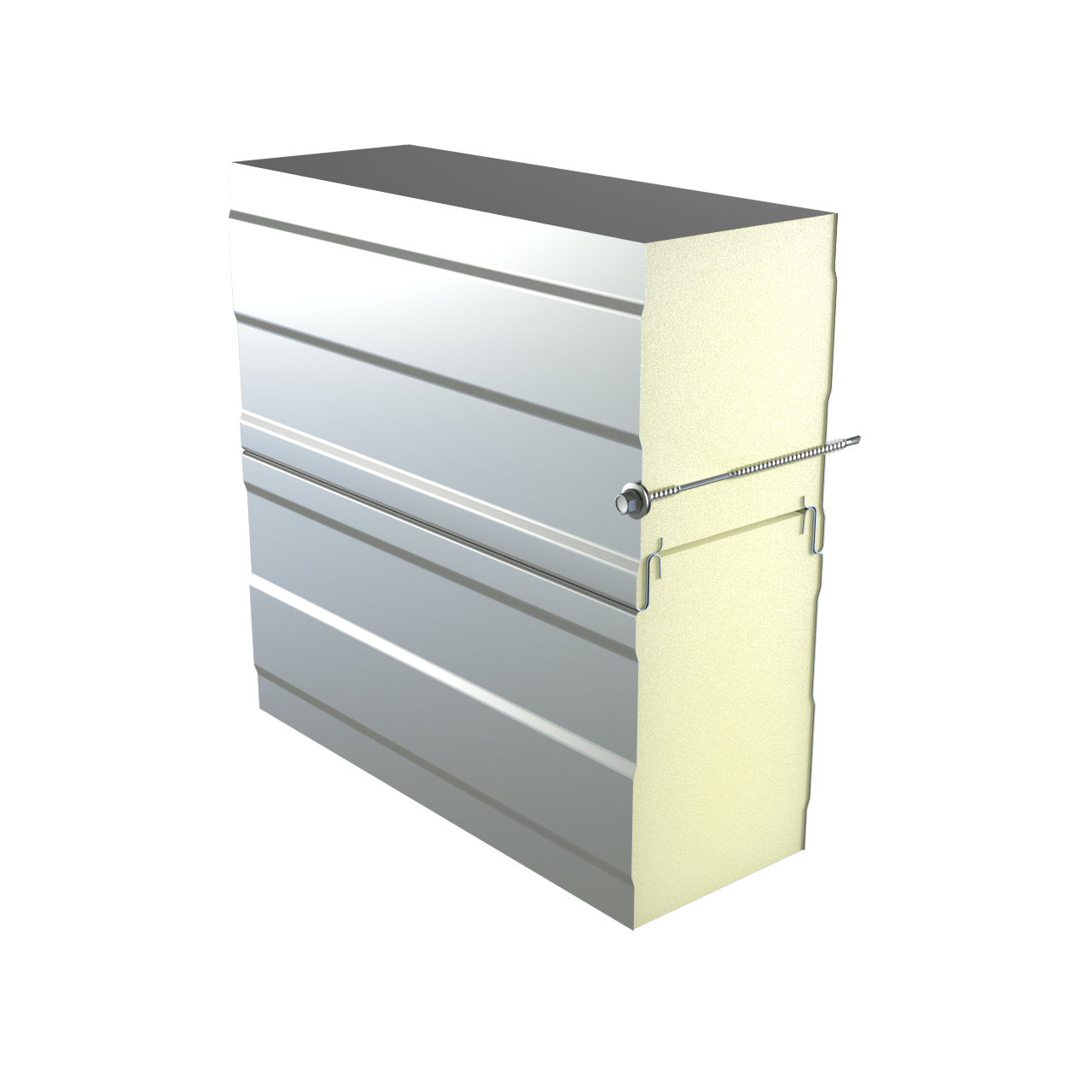

ISOSANOn RF thermal insulation wall panels

ISOSANOn RF panels are thermal insulation solutions with visible fastening and PIR foam core, designed for spaces that require high standards of hygiene and safety. The metal faces are covered with PVC, PE film or other finishes, customized according to the requirements of each project.

| Core | PIR polyisocyanurate foam |

| Interior sheet thicknesses | 0,50-0,60 mm |

| Exterior sheet thicknesses | 0,50-0,60 mm |

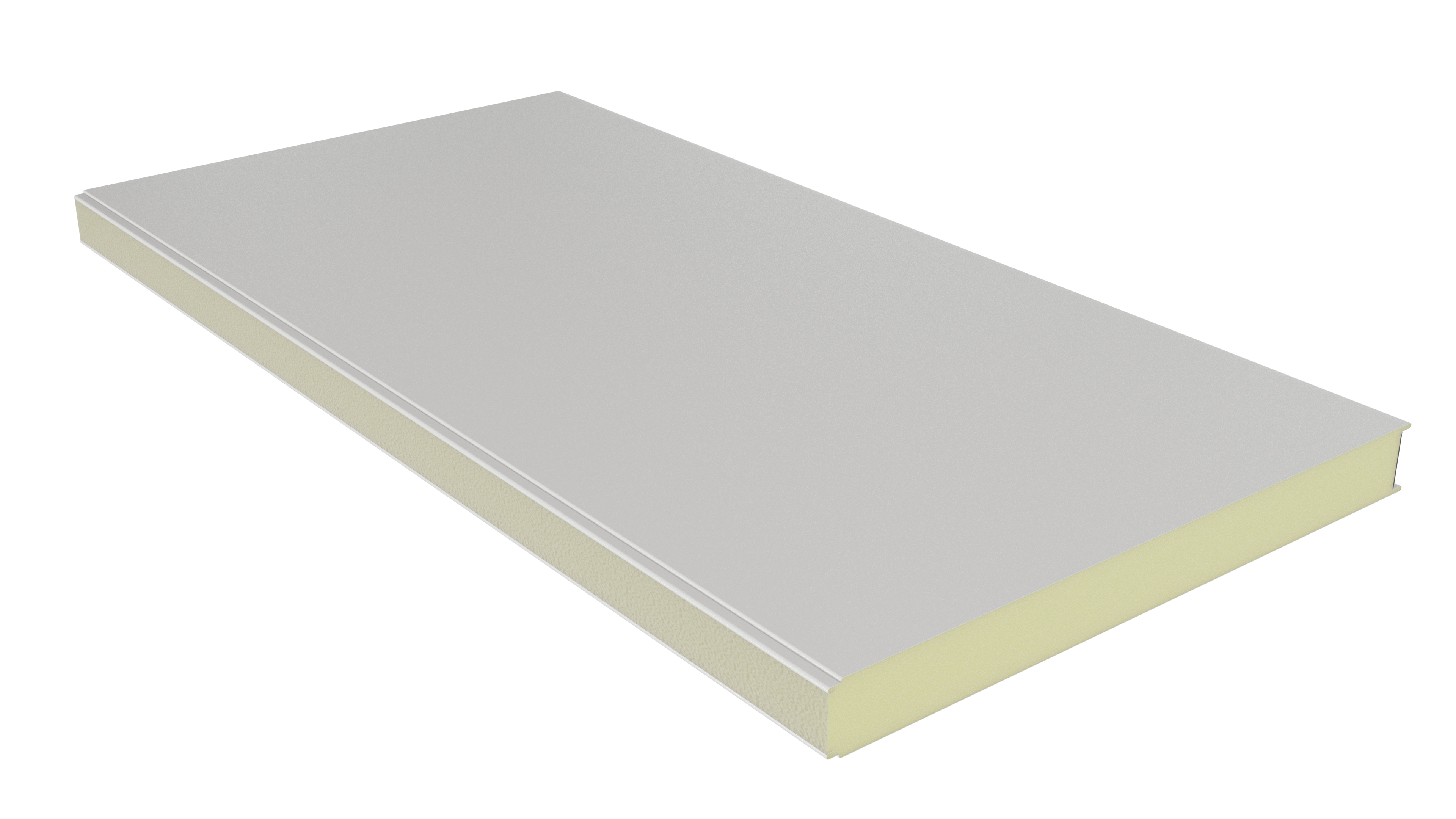

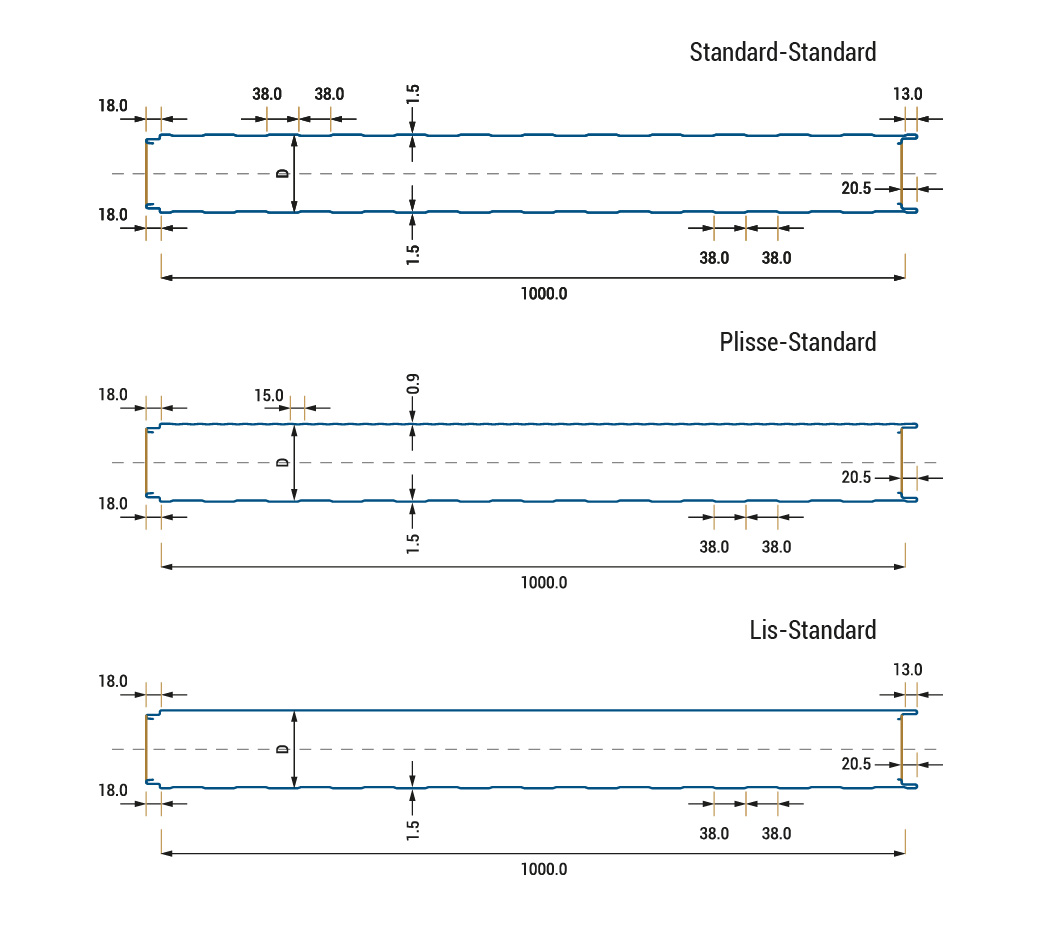

| Useful width | 1.000 mm |

| Minimum/maximum length | 2.000 mm – 13.500 mm |

| Panel thicknesses | 30, 40, 50, 60, 80, 100, 120 mm |

PIR foam offers excellent thermal insulation performance and contributes to construction safety, having stable fire behavior and not propagating the flame.

The panels can be installed both vertically and horizontally, easily adapting to different types of construction.

ISOSANOn RF is the ideal choice for the food industry, pharmaceutical industry, laboratories and other applications requiring a controlled hygienic environment.

An individual analysis of each project is recommended to ensure the optimal solution depending on the specifics of the application.

Details

Main characteristics

PIR (polyisocyanurate) foam sandwich panels stand out for their excellent performance in terms of fire resistance, thermal insulation and structural resistance at high temperatures.

Due to their high energy efficiency, they are the optimal solution for buildings that require high insulation standards.

The low weight contributes to fast and efficient transportation and assembly, and the variety of profiles and colors allows for aesthetic and functional integration into the building architecture.a

Due to their high energy efficiency, they are the optimal solution for buildings that require high insulation standards.

The low weight contributes to fast and efficient transportation and assembly, and the variety of profiles and colors allows for aesthetic and functional integration into the building architecture.a

Accessories

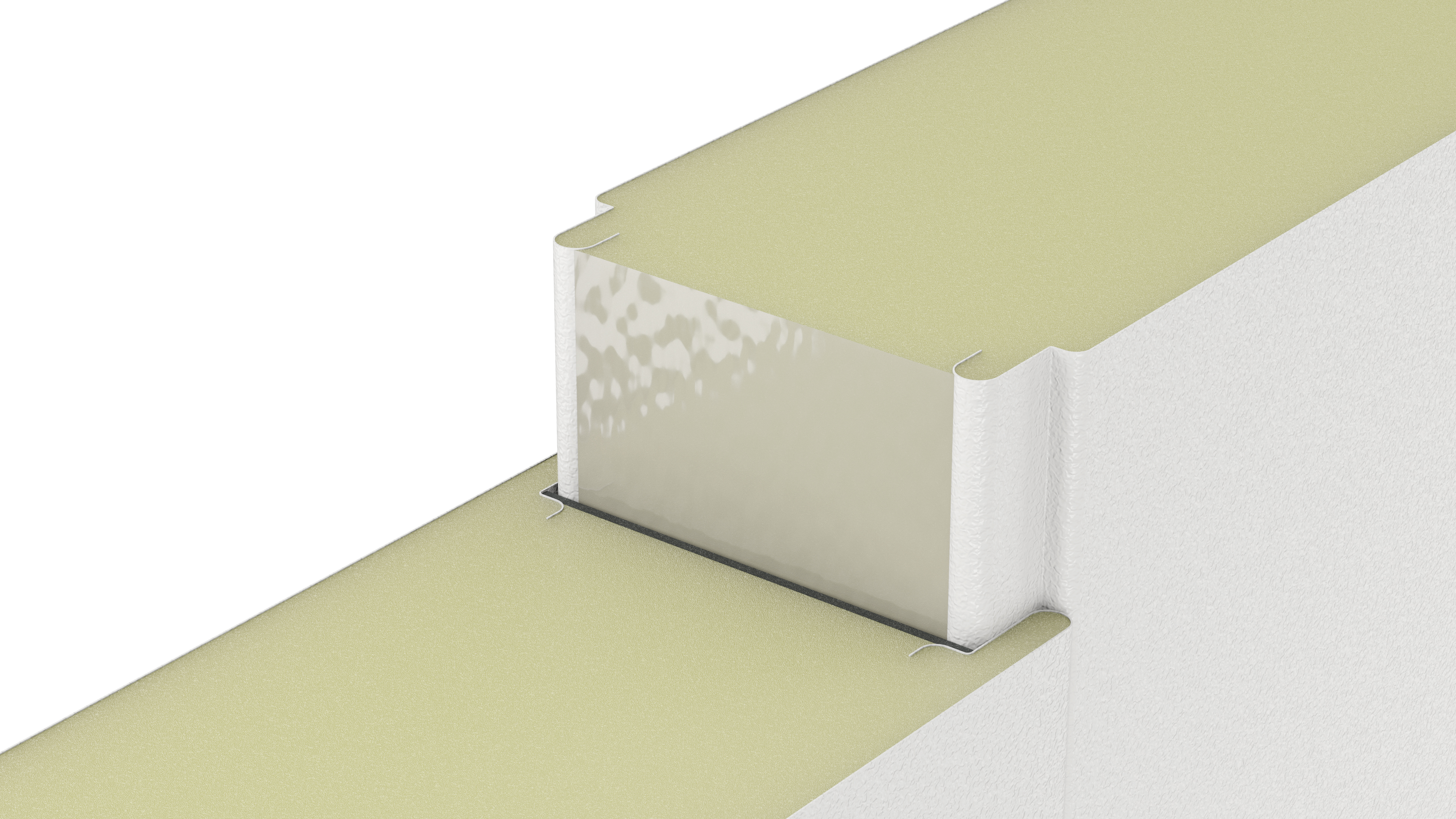

The screws are selected according to the nature of the structure to which they are fixed, the type and thickness of the panels. The number of fastening screws shall be 3 per 1 m width of the panel (one in the middle and two at the ends). For panels with concealed fastenings, the concealed edge shall be fastened with at least one screw at each intermediate support, and the ends shall be fastened outside the concealed screw with two additional screws, which shall be concealed afterwards.

Flashing profiles:

For joints between panels or around openings, use sheet metal profiles, fixed with at least 3 pop rivets/ml, for an aesthetic finish and additional protection.

Flashing profiles:

For joints between panels or around openings, use sheet metal profiles, fixed with at least 3 pop rivets/ml, for an aesthetic finish and additional protection.

Packing

The panels are delivered in packages wrapped in stretch film, on polystyrene supports. The number of panels in the package varies depending on the dimensions (thickness, length) and customer requirements, within the limits imposed by the manufacturing technology.

Wall panels are stacked in the package with the outer face (the blue film indicates the outer face for panel installation) facing up.

The packages have instructions on the minimum installation requirements and identification labels containing product characteristics: quantity, recipient, date of manufacture.

Wall panels are stacked in the package with the outer face (the blue film indicates the outer face for panel installation) facing up.

The packages have instructions on the minimum installation requirements and identification labels containing product characteristics: quantity, recipient, date of manufacture.

Other general characteristics

| Steel sheet material: | S220GD - S250GD pre-painted steel sheet, according to SR EN 10143:2006, SR EN 10346:2015 and SR EN 10169:2022 |

| Available coatings | Poliester, PVC, PVDF |

| Thermal conductivity (λ) according to SR EN 14509:2013 | declared 0,027 [W/mK], initial: 0,024 [W/mK] |

| Reaction to fire tested and approved to be in compliance with SR EN 14509:2013 | B-s2, d0 |